5 Tips & Trends for 2025: tip #2: In-house pretesting

In-house pretesting is a wise investment that saves time and money. In a series of five posts, our specialists share trends and developments for 2025.

Many EMC/Antenna test chambers were built in the 1990s or earlier. The question arises as to whether these rooms still meet the current technical specifications, the latest editions of EMC test standards and modern health & safety requirements. Unfortunately, in many cases, they do not. As a result, users are faced with a dilemma: whether to invest in a new test chamber or to renovate and upgrade the existing one. Comtest Engineering has the perfect solutions for both options, but in particular, sees a sharply increased demand for renovated/upgraded test rooms.

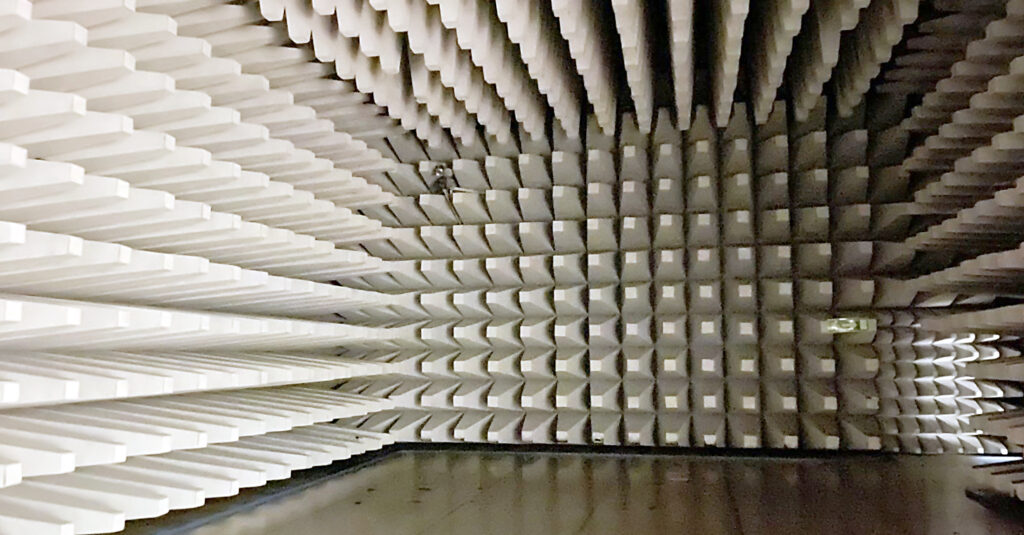

Uliana Trucchi, Senior Technical Consultant at Comtest, explains what can be wrong with outdated test chambers: “There are many SAC-3 and SAC-10 test chambers in Europe, some of which are already thirty or forty years old. At first glance, many rooms are still perfectly usable, but if you take a closer look, it turns out that something more is going on. Take the cone-shaped absorbers that line the walls. These are often made of PU foam, which has the disadvantage that the carbon disappears over the years, and the cone crumbles.

This adversely affects the damping effect and entails certain health risks. This is partly because this material is also made fire-resistant with certain chemical substances. People who often work in outdated test chambers are, therefore, exposed to toxic substances. For that reason alone, renovating/upgrading older test chambers is not an unnecessary luxury.”

New technology

“In addition to creating a healthier working environment, it is also exciting to renovate and upgrade a test chamber for technical reasons,” Trucchi continues. “For example, new absorbers are currently available from Dutch Microwave Absorber Solutions (DMAS), a sister company of Comtest, that are superior to the commonly used polyurethane absorbers.

DMAS absorbers are made of polystyrene, producing a much cleaner and more durable end product than polyurethane. In addition to the fact that no substances from the material are released into the room, which results in a healthier working environment, the new DMAS absorbers also have much better signal-dampening properties. This has to do with the better properties of the material used and the better and sharper cone shape, which gives the room a better damping factor. This increases the quality and reliability of EMC tests.

No hazardous materials or substances are used during the production of DMAS absorbers, making this a much better environmental solution than the well-known PU absorbers. In addition, the material used by DMAS is fire-retardant, resistant to both moisture and changes in ambient temperature, and is therefore characterised by an extremely long lifespan. It is ideal for upgrading existing test chambers.”

Start with testing

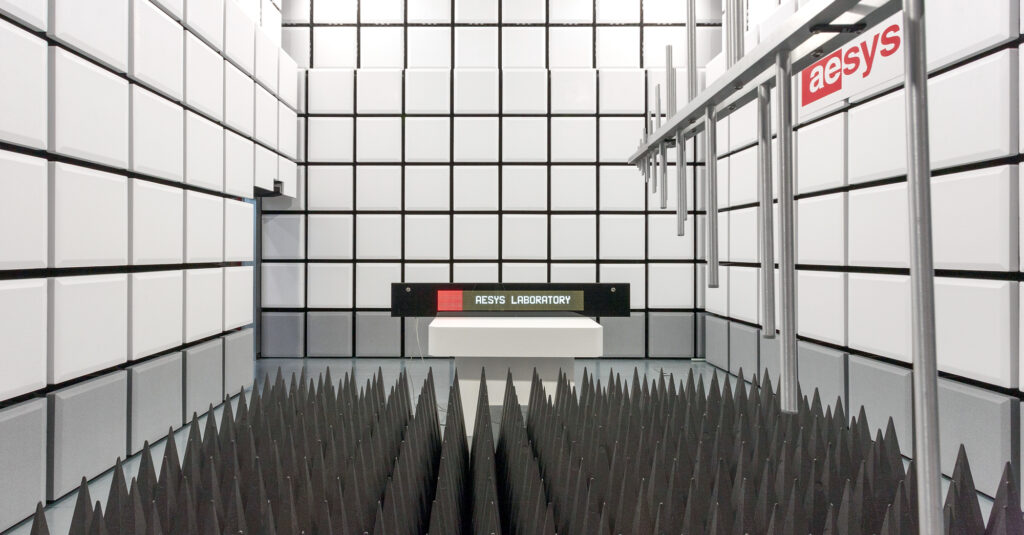

How does a renovation/upgrade of an existing test chamber work? Trucchi explains: “When upgrading an existing test chamber, one of the most crucial aspects is the ferrite tiles that dampen the signals below 1 GHz. It’s important to combine the existing ferrite tiles with new DMAS absorbers to improve the damping. However, it’s crucial to ensure that the combination of both types of absorbers works well together. Before starting the renovation, the operation of the existing ferrite tiles is thoroughly tested in the Comtest laboratory to ensure a good impedance matching between the existing ferrites and the new polystyrene absorbers from DMAS. Only after this test is complete can the renovation proceed without the risk of not meeting the chamber validation criteria of CISPR16-1-4.”

“In addition to the above, several other tests are conducted in advance, including a structural assessment of the test chamber. This includes examining the condition of the metal shielding panels in the walls, ceiling, and floor, as well as assessing the condition of the metal ground plane, the turn table and antenna mast, and all the access points. All these factors are crucial in evaluating the technical suitability of the room for renovation.”

Economic solution

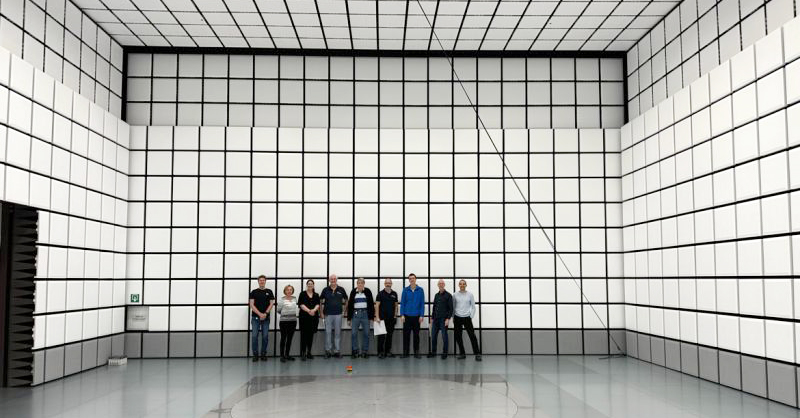

“A major advantage of renovation is that it is much cheaper than if a new test chamber has to be built,” Trucchi emphasises. “A new SAC-3 test chamber, for example, will require approximately three times as much investment as a test chamber renovated by us. Renovation is also much faster. In new construction, the existing room must first be dismantled and removed, sometimes taking up to two months. Renovation is possible if properly prepared and planned in one to two weeks. This means that the test facility is out of use for a much shorter time. We remove the old absorber material, which the customer shall dispose of following the local regulations. The new absorber layer is applied, and the renovated room is extensively tested before we hand it over to the customer.”

Better result

“Not only does renovation create a ‘like new’ test chamber, but in many cases, the usability also becomes much better,” says Trucchi. “The absorption of higher frequencies, in particular, is significantly improved thanks to the new DMAS absorber material. The limit can often be moved upwards to values up to 50 GHz. Comtest has already renovated/upgraded dozens of test chambers, and there has been a huge increase in renovation requests, especially in recent years. The market is large because many test chambers were built about thirty to forty years ago, and the majority of them have crumbling PU absorbers that need to be replaced. We have a perfect solution for this with the new, sustainable absorber solutions from DMAS.”

If you want a consultation to upgrade your EMC or antenna test chamber, contact Uliana Trucchi or her colleagues Hanneke van Veen or Marc Le Roy.

In-house pretesting is a wise investment that saves time and money. In a series of five posts, our specialists share trends and developments for 2025.

Electronic devices create radiated electromagnetic emissions that can be intercepted and reconstructed into data. In a series of five posts, our specialists share trends and

COMTEST

Hoge Rijndijk 205 | 2382 AL Zoeterwoude | The Netherlands | +31 71 541 7531 | Send us an email

Privacy Policy © Comtest 2024

COMTEST ENGINEERING BV

Hoge Rijndijk 205 | 2382 AL Zoeterwoude | The Netherlands | +31 71 541 7531 | Send us an email

Privacy Policy © Comtest Engineering 2024

Our services include maintenance and validated testing. We recommend that both are executed by authorized personnel only. Our expert teams can perform preventive maintenance on RF-shielded doors, mode-stirrer systems, and positioning equipment such as turntables. We also offer validation services to see if your EMC test chamber or RF-shielded room still functions within its intended limits and avoiding unexpected down-time or product recalls at the same time.

Our services include maintenance and validated testing. We recommend that both are executed by authorized personnel only. Our expert teams can perform preventive maintenance on RF-shielded doors, mode-stirrer systems, and positioning equipment such as turntables. We also offer validation services to see if your EMC test chamber or RF-shielded room still functions within its intended limits and avoiding unexpected down-time or product recalls at the same time.

A shielded room can perform conducted emission and immunity EMC measurements, eliminating harmful external influences, leading to more accurate and consistent test results. Being a Faraday cage, a shielded room will not only improve test results but will also form an excellent aid in protecting information and essential hardware. Comtest can assist governments, the military, financial institutions, and large corporations in protecting what matters most in critical situations. We offer the highest quality, sensitivity, and security before, during and after working with you.

A shielded room can perform conducted emission and immunity EMC measurements, eliminating harmful external influences, leading to more accurate and consistent test results. Being a Faraday cage, a shielded room will not only improve test results but will also form an excellent aid in protecting information and essential hardware. Comtest can assist governments, the military, financial institutions, and large corporations in protecting what matters most in critical situations. We offer the highest quality, sensitivity, and security before, during and after working with you.

Comtest has been building high-quality antenna test ranges for more than 20 years. We are dedicated to putting our experience to work for you, turning any problem you might have into a customized test solution. As for researching and developing your products, we know speed and return on investment are very important. That’s why we ensure your project is delivered on schedule, on budget and exactly as ordered.

Comtest has been building high-quality antenna test ranges for more than 20 years. We are dedicated to putting our experience to work for you, turning any problem you might have into a customized test solution. As for researching and developing your products, we know speed and return on investment are very important. That’s why we ensure your project is delivered on schedule, on budget and exactly as ordered.

Comtest offers semi and full anechoic chambers that shield almost 100% of ambient emissions and reflect minimal internal radiation. We deliver or build your custom test chamber at your location, depending on what size chamber you need. If you tell us your challenges, we’ll offer a tailored turnkey solution from design to installation, including upgrades and yearly certifications.

We are committed to helping you achieve the best EMC testing possible.

Comtest offers semi and full anechoic chambers that shield almost 100% of ambient emissions and reflect minimal internal radiation. We deliver or build your custom test chamber at your location, depending on what size chamber you need. If you tell us your challenges, we’ll offer a tailored turnkey solution from design to installation, including upgrades and yearly certifications.

We are committed to helping you achieve the best EMC testing possible.