A new component test chamber for Booz Allen Hamilton

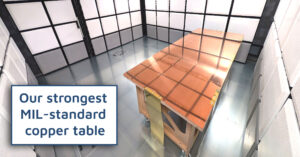

This table can support objects weighing up to 750 kilograms and complies with MIL-Standard for the defence industry. Let us share more details about our production line’s strongest testing table.

PIM has been highlighted as a growing problem for cellular network providers and associated equipment suppliers. This type of interference can reduce receiver sensitivity and, in some cases, may even completely inhibit communication. Recognising and mitigating the PIM problem is thus essential for increasing system reliability and reducing operation costs. In this post, we attempt to review the sources and causes of PIM and the solutions proposed to detect and solve it.

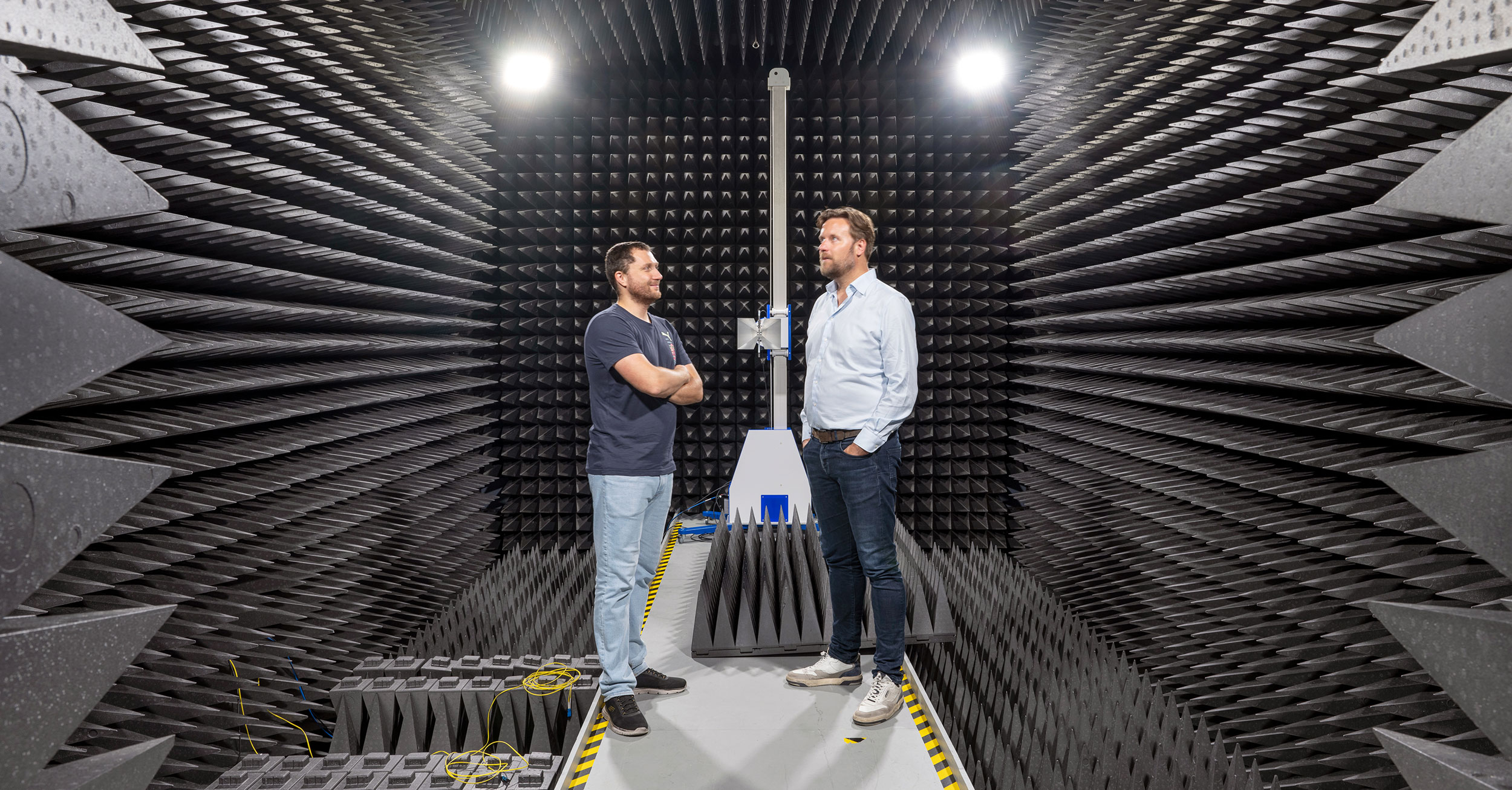

Our colleague, Dmitriy Penkin (in the photo on the left), explains why awareness of this problem is essential. “PIM stands for Passive Intermodulation. It refers to the intermodulation products generated when two or more signals transit through a passive device with nonlinear properties. These nonlinearities typically arise from the interaction of mechanical components and can seriously impact overall system performance. Their examples include the junction of two different metals, loose cable connections, dirty connectors, underperforming duplexers, aged antennas and the like.”

And how can telecommunication companies prevent PIM from happening?

Dmitriy: “Base stations and mobile equipment OEMs must secure reliable communications. Accurate PIM measurements and related troubleshooting campaigns are only possible in an anechoic chamber that is properly designed and characterised by very low PIM levels, such as the chamber in the photo we built for a large telecom provider. At our Comtest R&D department, we apply extensive and expanding knowledge to equip our clients with a chamber solution designed as ‘PIM-free’: such a test chamber has an aluminium shielding enclosure since we aim to replace all ferromagnetic materials with non-magnetic alternatives. Think also of specific aluminium or plastic screws, wooden test benches, special rails and more. Last but not least, we continuously work on optimising microwave absorbing material to ensure minimal nonlinearities within the anechoic chamber.”

For more information on our test chamber solutions for PIM testing, please contact Marc Le Roy, Hanneke Mertens – van Veen or Uliana Trucchi.

This table can support objects weighing up to 750 kilograms and complies with MIL-Standard for the defence industry. Let us share more details about our production line’s strongest testing table.

We were surprised by the results of our poll to determine if the market prefers end caps on their absorbers. The results were quite clear! Two responses received 88% of the votes, leaving little room for the other two options.

COMTEST

Hoge Rijndijk 205 | 2382 AL Zoeterwoude | The Netherlands | +31 71 541 7531 | Send us an email

Privacy Policy © Comtest 2025

COMTEST ENGINEERING BV

Hoge Rijndijk 205 | 2382 AL Zoeterwoude | The Netherlands | +31 71 541 7531 | Send us an email

Privacy Policy © Comtest Engineering 2025

Our services include maintenance and validated testing. We recommend that both are executed by authorized personnel only. Our expert teams can perform preventive maintenance on RF-shielded doors, mode-stirrer systems, and positioning equipment such as turntables. We also offer validation services to see if your EMC test chamber or RF-shielded room still functions within its intended limits and avoiding unexpected down-time or product recalls at the same time.

Our services include maintenance and validated testing. We recommend that both are executed by authorized personnel only. Our expert teams can perform preventive maintenance on RF-shielded doors, mode-stirrer systems, and positioning equipment such as turntables. We also offer validation services to see if your EMC test chamber or RF-shielded room still functions within its intended limits and avoiding unexpected down-time or product recalls at the same time.

A shielded room can perform conducted emission and immunity EMC measurements, eliminating harmful external influences, leading to more accurate and consistent test results. Being a Faraday cage, a shielded room will not only improve test results but will also form an excellent aid in protecting information and essential hardware. Comtest can assist governments, the military, financial institutions, and large corporations in protecting what matters most in critical situations. We offer the highest quality, sensitivity, and security before, during and after working with you.

A shielded room can perform conducted emission and immunity EMC measurements, eliminating harmful external influences, leading to more accurate and consistent test results. Being a Faraday cage, a shielded room will not only improve test results but will also form an excellent aid in protecting information and essential hardware. Comtest can assist governments, the military, financial institutions, and large corporations in protecting what matters most in critical situations. We offer the highest quality, sensitivity, and security before, during and after working with you.

Comtest has been building high-quality antenna test ranges for more than 20 years. We are dedicated to putting our experience to work for you, turning any problem you might have into a customized test solution. As for researching and developing your products, we know speed and return on investment are very important. That’s why we ensure your project is delivered on schedule, on budget and exactly as ordered.

Comtest has been building high-quality antenna test ranges for more than 20 years. We are dedicated to putting our experience to work for you, turning any problem you might have into a customized test solution. As for researching and developing your products, we know speed and return on investment are very important. That’s why we ensure your project is delivered on schedule, on budget and exactly as ordered.

Comtest offers semi and full anechoic chambers that shield almost 100% of ambient emissions and reflect minimal internal radiation. We deliver or build your custom test chamber at your location, depending on what size chamber you need. If you tell us your challenges, we’ll offer a tailored turnkey solution from design to installation, including upgrades and yearly certifications.

We are committed to helping you achieve the best EMC testing possible.

Comtest offers semi and full anechoic chambers that shield almost 100% of ambient emissions and reflect minimal internal radiation. We deliver or build your custom test chamber at your location, depending on what size chamber you need. If you tell us your challenges, we’ll offer a tailored turnkey solution from design to installation, including upgrades and yearly certifications.

We are committed to helping you achieve the best EMC testing possible.