A new component test chamber for Booz Allen Hamilton

This table can support objects weighing up to 750 kilograms and complies with MIL-Standard for the defence industry. Let us share more details about our production line’s strongest testing table.

This table can support objects weighing up to 750 kilograms and complies with MIL-Standard for the defence industry. Let us share more details about our production line’s strongest testing table.

We were surprised by the results of our poll to determine if the market prefers end caps on their absorbers. The results were quite clear! Two responses received 88% of the votes, leaving little room for the other two options.

COMTEST

Hoge Rijndijk 205 | 2382 AL Zoeterwoude | The Netherlands | +31 71 541 7531 | Send us an email

Privacy Policy © Comtest 2025

COMTEST ENGINEERING BV

Hoge Rijndijk 205 | 2382 AL Zoeterwoude | The Netherlands | +31 71 541 7531 | Send us an email

Privacy Policy © Comtest Engineering 2025

Our services include maintenance and validated testing. We recommend that both are executed by authorized personnel only. Our expert teams can perform preventive maintenance on RF-shielded doors, mode-stirrer systems, and positioning equipment such as turntables. We also offer validation services to see if your EMC test chamber or RF-shielded room still functions within its intended limits and avoiding unexpected down-time or product recalls at the same time.

Our services include maintenance and validated testing. We recommend that both are executed by authorized personnel only. Our expert teams can perform preventive maintenance on RF-shielded doors, mode-stirrer systems, and positioning equipment such as turntables. We also offer validation services to see if your EMC test chamber or RF-shielded room still functions within its intended limits and avoiding unexpected down-time or product recalls at the same time.

A shielded room can perform conducted emission and immunity EMC measurements, eliminating harmful external influences, leading to more accurate and consistent test results. Being a Faraday cage, a shielded room will not only improve test results but will also form an excellent aid in protecting information and essential hardware. Comtest can assist governments, the military, financial institutions, and large corporations in protecting what matters most in critical situations. We offer the highest quality, sensitivity, and security before, during and after working with you.

A shielded room can perform conducted emission and immunity EMC measurements, eliminating harmful external influences, leading to more accurate and consistent test results. Being a Faraday cage, a shielded room will not only improve test results but will also form an excellent aid in protecting information and essential hardware. Comtest can assist governments, the military, financial institutions, and large corporations in protecting what matters most in critical situations. We offer the highest quality, sensitivity, and security before, during and after working with you.

Comtest has been building high-quality antenna test ranges for more than 20 years. We are dedicated to putting our experience to work for you, turning any problem you might have into a customized test solution. As for researching and developing your products, we know speed and return on investment are very important. That’s why we ensure your project is delivered on schedule, on budget and exactly as ordered.

Comtest has been building high-quality antenna test ranges for more than 20 years. We are dedicated to putting our experience to work for you, turning any problem you might have into a customized test solution. As for researching and developing your products, we know speed and return on investment are very important. That’s why we ensure your project is delivered on schedule, on budget and exactly as ordered.

Comtest offers semi and full anechoic chambers that shield almost 100% of ambient emissions and reflect minimal internal radiation. We deliver or build your custom test chamber at your location, depending on what size chamber you need. If you tell us your challenges, we’ll offer a tailored turnkey solution from design to installation, including upgrades and yearly certifications.

We are committed to helping you achieve the best EMC testing possible.

Comtest offers semi and full anechoic chambers that shield almost 100% of ambient emissions and reflect minimal internal radiation. We deliver or build your custom test chamber at your location, depending on what size chamber you need. If you tell us your challenges, we’ll offer a tailored turnkey solution from design to installation, including upgrades and yearly certifications.

We are committed to helping you achieve the best EMC testing possible.

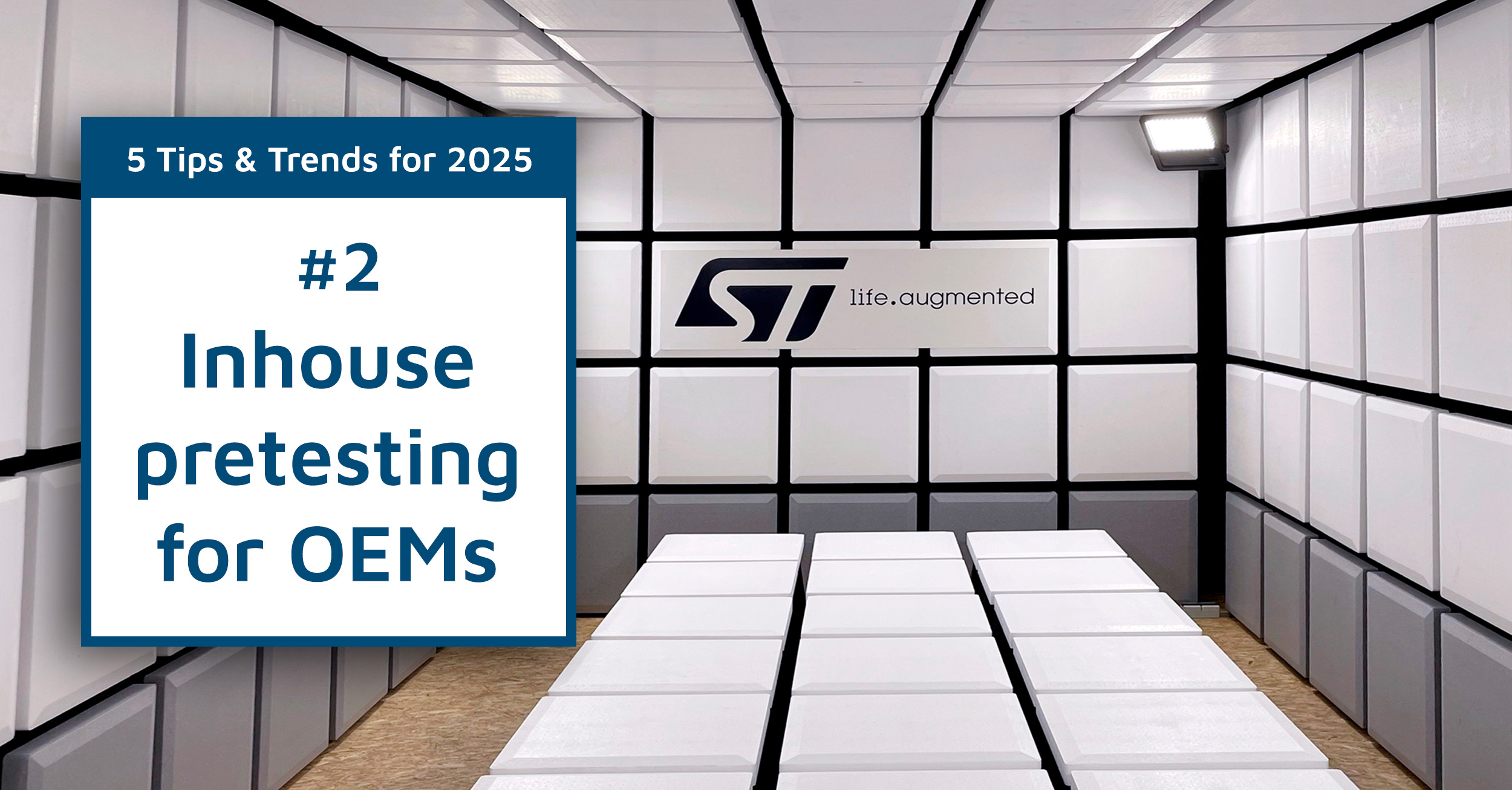

In-house pretesting is a wise investment that saves time and money. In a series of five posts, our specialists share trends and developments for 2025. This week, Technical Consultant Uliana Trucchi will discuss the future of in-house pretesting for OEMs.

Uliana: “More and more products contain electronics that require testing. Many OEMs use test houses to pretest their products before the final certification. That creates a challenge because test houses are sometimes hard to book quickly, and the out-of-pocket costs pile up. I predict that more and more OEMs will consider in-house pretesting to secure their time-to-market and control costs. And honestly, you do not need to go to a test house for every step in the product development.”

Can certification be done in-house as well? Uliana: “OEMs can self-certify, but you have to be confident and well-prepared with a good correlation between the test executed in your pre-compliant chamber and the fully compliant one at the final certification body, and the investment in a pre-compliant chamber is doable. However, to be sure you correlate correctly, send your products to an external test house occasionally.”

The photo shows an example of a pre-compliant chamber we built in Grenoble (F).

Are in-house pretesting and self-certification options for you? Contact Marc Le Roy, Uliana Trucchi, Vincent van de Vrie, or Hanneke Mertens – van Veen to find out.