Exchanging Fast-stirring and ISO 11451-5 knowledge in Japan

Last week, our consultants, Hanneke van Veen and Dimitrios Barakos, visited seven companies in Japan with our friends from Microwave Factory to help companies implement the closed-loop power control (fast stirring) reverb method as per the ISO11451-5 test standards.

Testing time is valuable, so this post provides tips on optimising the number of stirrer positions in your reverberation chamber to fit your budget and test requirements. “There is a delicate balance between the number of stirrer positions and the amplifier power for a given reverberation chamber,” explains our R&D Consultant, Dimitrios Barakos. By collaborating with EMC test solution provider Rohde & Schwarz, we aim to find the most efficient solution for our clients. “

Dimitrios: “The lowest frequency of operation dictates the chamber size and should be considered during initial design. The amplifier power required to generate a particular field level for the chosen size of the chamber can be reduced by increasing the number of stirrer steps. However, a minimum number of stirrer steps is required to achieve a certain field uniformity. Therefore, we prefer to design a chamber with the lowest usable frequency in mind that can accommodate more stirrer steps than required, with the possibility of reducing the stirrer steps in the future. This approach will help reduce test time but will require larger amplifier power. Upgrading the amplifier is easier than upgrading the chamber size. Building and calibrating a new chamber takes a lot of time; as you know, time is money.”

Rohde & Schwarz’s EMC Solution Specialist for the Nordics, Martin Randrup Villadsen, advises, “The balance of amplifier power and stirrer steps can impact investment cost and test time. A good compromise can be to allocate a budget for an amplifier upgrade if needed. Rohde & Schwarz’s family of configurable broadband amplifiers with scalable frequency and power levels make this easy.”

We know a perfect solution might sound complicated. So, to help, you can always contact one of our technical consultants, Vincent van de Vrie, Hanneke Mertens – van Veen, Uliana Trucchi, or Marc Le Roy, to explore a sustainable solution for your needs.

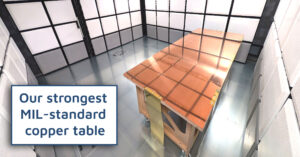

In the video: the LUF200 reverberation chamber with a dual-stirrer setup for close-loop testing (fast-stirring) as per ISO-11451-5 at the Rohde & Schwarz Asia-Pacific hub in Singapore.